CONTACT US

GLIDEWELL

SPECIALTIES

FOUNDRY

© 2024 GLIDEWELL SPECIALTIES FOUNDRY, ALL RIGHTS RESERVED

(205) 668-1972

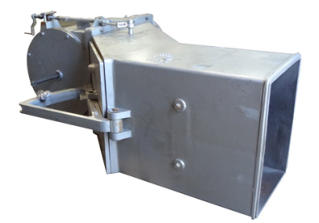

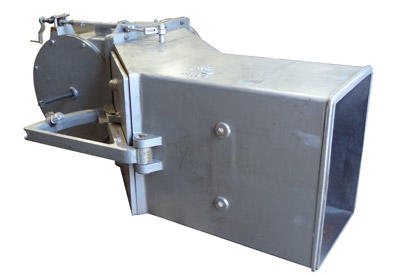

At Glidewell, we specialize in the casting and machining of ductile and gray iron.

These capabilities are highlighted in the projects shown here. These items were

fabricated for a manufacturer of steel mill equipment and coke ovens, whose

volume and nature required a high degree of precision and consistency.

Composed of ductile iron the projects consisted of six meter coke oven door

jambs, wall protection plates, air boxes, goosenecks, and various hooks, levers,

and fasteners. These items represent castings totaling over 5,400 lbs., all of which

were molded and cast with advanced automated and semi-automated

equipment. After casting, all parts were machined per customer specifications,

which required tolerances of ± 0.015" prior to assembly.

All of these components are subject to our stringent quality control program, which in this case includes magnetic particle

inspection, and radiography. Components are manufactured in orders of 1 to 85 pieces with lead times of 10 to 14 weeks.

To learn more about these projects, or the processes used top complete it, see the table below or contact us directly.

Casting of Ductile Iron Components

CONTACT US

GLIDEWELL

SPECIALTIES

FOUNDRY

© 2024 GLIDEWELL SPECIALTIES FOUNDRY, ALL RIGHTS RESERVED

(205) 668-1972

At Glidewell, we

specialize in the casting

and machining of

ductile and gray iron.

These capabilities are

highlighted in the

projects shown here.

These items were fabricated for a manufacturer of

steel mill equipment and coke ovens, whose

volume and nature required a high degree of

precision and consistency.

Composed of ductile iron the projects consisted of

six meter coke oven door jambs, wall protection

plates, air boxes, goosenecks, and various hooks,

levers, and fasteners. These items represent

castings totaling over 5,400 lbs., all of which were

molded and cast with advanced automated and

semi-automated equipment. After casting, all parts

were machined per customer specifications, which

required tolerances of ± 0.015" prior to assembly.

All of these components are subject to our

stringent quality control program, which in this

case includes magnetic particle inspection, and

radiography. Components are manufactured in

orders of 1 to 85 pieces with lead times of 10 to 14

weeks.

To learn more about these projects, or the

processes used top complete it, see the table below

or contact us directly.

Casting of Ductile Iron

Components

CONTACT US

GLIDEWELL

SPECIALTIES

FOUNDRY

© 2024 GLIDEWELL SPECIALTIES FOUNDRY, ALL RIGHTS RESERVED

(205) 668-1972

At Glidewell, we specialize in the casting and machining of ductile and gray iron.

These capabilities are highlighted in the projects shown here. These items were

fabricated for a manufacturer of steel mill equipment and coke ovens, whose

volume and nature required a high degree of precision and consistency.

Composed of ductile iron the projects consisted of six meter coke oven door

jambs, wall protection plates, air boxes, goosenecks, and various hooks, levers,

and fasteners. These items represent castings totaling over 5,400 lbs., all of which

were molded and cast with advanced automated and semi-automated equipment.

After casting, all parts were machined per customer specifications, which required

tolerances of ± 0.015" prior to assembly.

All of these components are subject to our stringent quality control program, which in this case includes magnetic particle

inspection, and radiography. Components are manufactured in orders of 1 to 85 pieces with lead times of 10 to 14 weeks.

To learn more about these projects, or the processes used top complete it, see the table below or contact us directly.

Casting of Ductile Iron Components